Teledyne Shareholder Letters by Henry Singleton

Everyone knows and studies Buffett, Munger, and Berkshire but many of the things we associate with Buffett and Berkshire were first employed by Singleton at Teledyne.

“Henry Singleton has the best operating and capital deployment record in American business.” — Warren Buffett, chairman and CEO of Berkshire Hathaway

“His results are a mile higher than anyone else… utterly ridiculous.” — Charlie Munger, vice chairman of Berkshire Hathaway

Everyone knows and studies Buffett, Munger, and Berkshire, but far fewer even know of Henry Singleton and his conglomerate Teledyne that went public in 1961. But many of the things we associate with Buffett and Berkshire were first employed by Singleton at Teledyne.

Singleton was more engineer than MBA, and like Buffett he say himself as more investor than operator. Teledyne was a notoriously decentralized operation, except when it came to capital allocation, much like Berkshire. He avoided Wall Street analysts and chose cash flow over reported earnings.

Over his tenure, Teledyne would acquire more than 120 companies across a variety of, often deeply technical, industries. But his approach to investing was dead simple: Buy back shares when they were cheap, issue them when they were highly valued, and then use the proceeds from operations and share issuance to buy more wonderful businesses.

Singleton ran Teledyne for almost thirty years, and compounded his investments at an extraordinary 20.4 percent per annum. If you had invested a dollar with Singleton in 1963, by 1990, when he retired as chairman in the teeth of a severe bear market, it would have been worth $180. That same dollar invested in a broad group of conglomerates would have been worth only $27, and $15 if invested in the S&P 500.

That’s why I feel safe saying that Singleton’s Teledyne Shareholder Letters are a must read for capital allocators and business leaders alike.

1961 Teledyne Shareholder Letter

This report presents the results of your company’s first year of operation. Sales for the year totalled $4,491,431. Consolidated net after-tax earnings amounted to $133,190, or twenty-five cents per share on the 519,550 shares outstanding at year-end. Additional income of $40,4851, excluded in the consolidation, raise earnings to $173,675, or thirty-three cents per share. Backlog of the company increased throughout the year, and at present totals more than $10,000,000.

Your company’s objective has been from the beginning to become a major developer and manufacturer of a broad line of electronic systems and equipments, and of the electronic instruments and components that go in such systems. Key elements supporting this objective are:

The establishment of a profitable and expanding operating base, and

The assembly and effective utilization of a strong research and development organization.

The company made substantial progress in both of these areas during the year.

The company’s operating based was expanded steadily throughout the year by a combination of acquisitions and internal growth. In October of 1960 Teledyne acquired 87.5% of the outstanding stock of Amelco, Inc. And all of the outstanding of Handley, Inc. and Mercury Transformer Corporation. These acquisitions gave the company eighty thousands square feet of floor space devoted to the development and manufacturing of electronic systems, data entry and readout equipment, magnetic devices and transformers, hight quality etched circuits and miniature trimmer potentiometers. Total employment in these corporations was about 200 people in November of 1960, and had more than doubled by year end. In July of 1961, Teledyne acquired Palmer Instruments of South Pasadena, California, with its excellent precision shop facilities and strong proprietary position in temperature control techniques and low frequency quartz crystals used in crystal filters and stable oscillators. In August of 1961 the acquisition of the minority interest in Amelco was completed, making all of the company’s subsidiaries wholly owned. Subsequent to the close of the fiscal year, the company acquired the assets and business of Linair Engineering, Inc., a leader in aircraft and missile pneumatic and hydraulic fittings, and through its subsidiaries a manufacturer of a variety of electronic components, including precision potentiometer business of Handley, Inc. and the quartz crystal business of Palmer Instruments have been consolidated with the electronic components business of Linair in a separate building in Hawthorne, California, under the name of Teledyne Precision, Inc.

Paralleling the growth of the company’s physical assets and capabilities have been the growth of its technical and development staff. The company now employs more than fifty engineers and scientists. During the year our technical people have been responsible for the acquisition of a variety of prime and subcontracts in the fields of electronic communications, data processing, computers, and automatic control equipment. Some of these contracts are for advanced research and development, others are for technical studies, while still others are for production of advanced equipment. Typical of these programs are the following: production of navigation computers for carrier-based antisubmarine aircraft, development of data processors for scientific satellites, an instrumentation study for design of space communication antennas, an adaptive (learning) computer for simulating neural networks, an air defense study, and an antisubmarine warfare study.

Subsequent to the close of the fiscal year the company received a $5 million contract for production of FADAC digital computers, scheduled to be used in the Army’s new artillery fire direction centers. This program, widely sought after in the industry, is expected to be of considerable significance to the company’s future.

In February of 1961, the company opened its Electron Devices Division in Mountain View, California, with the objective of developing proprietary manufacturing processes for the direct application of electronic solid state technology to the manufacture of electronic systems and equipment. Under the leadership of an outstanding group of scientists, this division has made notable progress. The division now employs fifty people. In addition to actively supporting the programs of the systems division in Los Angeles, at this writing the division is completing development of a number of new soldi state devices and special assemblies for sales to the industry.

During its first year, the company invested more than $350,000 in research and development. This program of company-sponsored research and development will be expanded in the future, as we continue with the development of proprietary products and the preparation of technical studies and proposals. The field of advanced electronics invites this kind of investment, and in return offers unlimited opportunities for growth. With the support of our shareholders and the dedicated efforts of our employees, we are confident that the company’s continued growth will be assured.

1962 Teledyne Shareholder Letter

This annual report covers fiscal year 1962, your company’s second year of operations. Sales for the year totalled $10,438,367, up 132% from the $4,491,431 of our first year. Earnings, net of applicable taxes, were $331,518, a gain of 148% over the $133,190 earned in 1961. Earnings per share advanced 100% amounting to 50 cents per share on the 654,857 shares outstanding at year end.

The company now has approximately 1,500 shareholders, the majority of whom were added during the past year. It therefore seems appropriate at this time to review certain of the company’s objectives and plans. From its inception the company has planned to become a major supplier, for military and industrial applications, of electronic end-item equipment and systems, and of the specialized electronic components that make up such systems. The various steps that have been taken to date in the company’s expansion reflect the implementation of this plan.

Systems and Equipment — At the present time, the business of our Electronic Systems Division may be classified into three principal categories:

communications equipment,

Computers and data systems, and

guidance and control systems.

Our work in these three fields spans the range from very advanced theoretical and experimental studies and research, through development and production. For example, in the communications area we are developing and producing advanced monopulse tracking receivers for the National Aeronautics and Space Administration, which are used in the global minitrack network for the tracking of satellites and space probes. We are also producing R-390 communication receivers and ARC-73 transmitter-receivers for the Army. In computers and data systems we are producing FADAC computers for the Army’s fire direction centers, and ASA-13A navigation computers for Navy anti-submarine patrol aircraft. For guidance and control applications we are developing high-acceleration inertial instruments for the Army Missile Command, and advanced accelerometers for the Air Force’s Aeronautical Systems Division. Systems and equipment business during the fiscal year accounted for approximately two-thirds of our total sales volume.

Precision Components — The company’s business in components increased throughout the year, and accounted for approximately one-third of total sales. Our present component activities may be classified as follows:

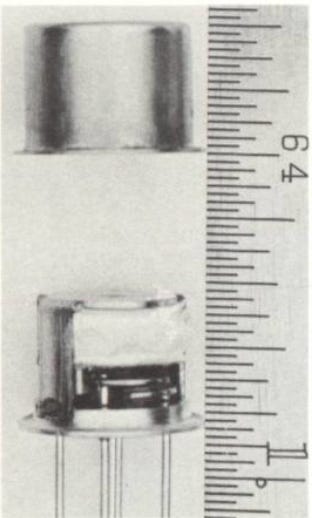

electromechnical devices, developed and produced by Teledyne Precision, Inc. This product line has now been broadened to include relays, potentiometers, switches, quartz crystals, and temperature controlled component enclosures. Particularly noteworthy in this group is our new relay, which we have been developing for over a year and which was first offered for sale by the company late in the year. Packaged in a standard transistor case, it is believed to be one of the world’s smallest and fastest relays;

hydraulic and pneumatic aircraft and missile fittings, a line of products added through the acquisition of Linair Engineering, one of the leading suppliers in this field;

transformers, an area in which our capability was considerably strengthened by the acquisition of Crittenden Transformer Works, Inc., an efficient design and manufacturing organization which has operated profitably under the same management for the past seventeen years; and

semiconductor devices and integrated circuits.

During the year our work in semiconductor devices and integrated circuits was greatly broadened, with employment in the Electron Devices Division of our wholly-owned subsidiary, Amelco, Inc., increasing from about 50 people to approximately 200 by year-end. An important element facilitating this unusually rapid expansion has been the development and production of high performance silicon planar transistors for our own computers and data systems. These advanced transistors and additional related types have proven to be popular with other equipment manufacturers, and we are now producing and selling them in increasing quantity. Such devices as the 2N709 and 2N917, the fastest silicon planar transistors available, are now in production in our plant; and we recently introduced the FE-200 and FE-300 field effect transistors —very high input impedance active devices, with amplification and control characteristics much like those of pentode vacuum tubes. The availability of these fundamentally new units to the electronic systems engineer provides him with a valuable element of versatility in circuit and systems design, and permits easy and advantageous solutions to many otherwise troublesome circuit design problems. We believe that our achievement of successful volume production of silicon field effect transistors represents a major step forward in device technology, and that these field effect devices may some day be as widely used as conventional transistors are today.

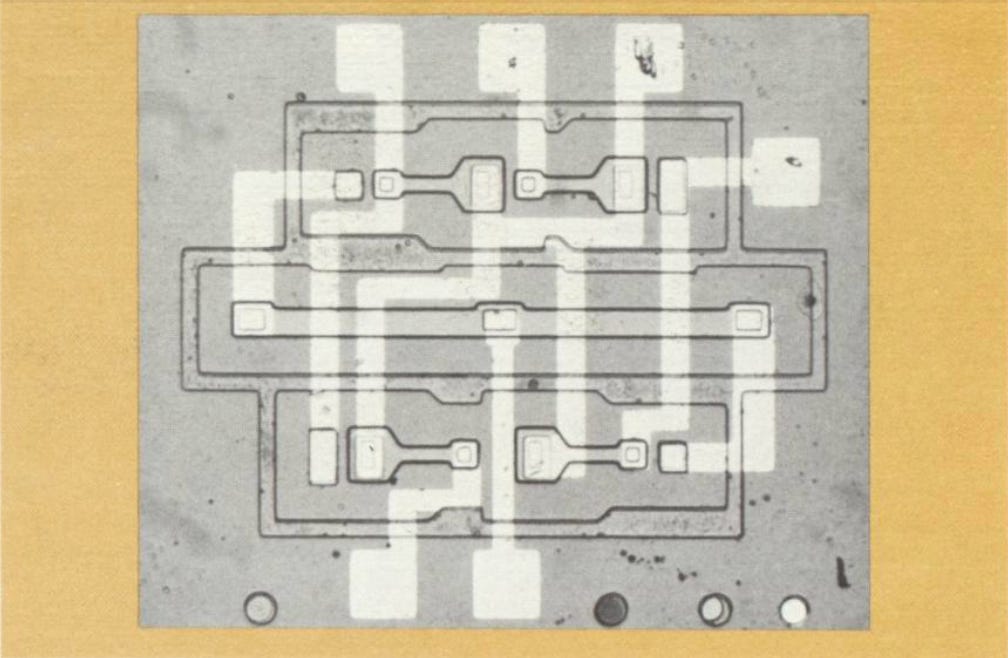

Simultaneously with the development of new and improved semiconductor devices, the Electron Devices Division has continued a substantial program in the development of integrated circuits. In this program, we are developing processes and techniques for applying electronic solid state technology directly to the production of complete circuits rather than individual circuit elements. The utilization of these processes will result in a significant improvement in the methods now used for the manufacture of electronic equipment. Initially, we are carrying out the development of a variety of special custom circuits for our own systems division and for other equipment manufacturers. In addition, we have developed and will shortly introduce to the market, a number of proprietary digital logic circuits such as gates and flip-flops. By providing greater reliability and reduced size and weight, together with a potential reduction in cost, such circuits as these are expected eventually to become widely used in the design and manufacture of digital computers and other digital equipment.

Facilities — To accomodate the increasing activities of our systems and components divisions, the company added substantially to its plant facilities during the year. We acquired a thirteen acre site in Hawthorne, California for the expansion of our Electronic Systems Division. We have 45,000 square feet in operation there now, and can add an additional 200,000 square feet as the occasion arises. For the expansion of the Electron Devices Division we acquired a fourteen acre site in Mountain View, California and are now constructing the initial 55,000 square foot building of a research, development and production complex at this location. Floor space now occupied by the company totals approximately 180,000 square feet.

Acquisitions — In addition to the acquisition of Linair Engineering and Crittenden Transformer, by which we broadened our component product base, our activities in electronic systems was strengthened by the acquisition of American Systems Incorporated, since renamed Teledyne Systems Corporation. This acquisition brought to us increased capability in digital computer programming know-how; in electromagnetic systems technology, including advanced antennas applicable to a variety of communications systems; and in control instrumentation as applied to the detection of propellant and oxidizer vapors at missile sites. We also made an investment during the year in Micronetics, Inc., a San Diego based company newly-formed to exploit a capability in the generation, detection and utilization of extremely short pulses of microwave energy. We acquired approximately 20% of the stock of this company, and have an option to acquire the rest under specified conditions.

Stock Options — Some of our newer shareholders may be interested in the company’s restricted stock option plan. The use of stock options to attract outstanding key personnel to our company has proven to be particularly effective. Without this ability it would have been extremely difficult, if not impossible, to have brought into the company so many highly qualified technical and management personnel in such a short period of time. The careful use of our option plan has been especially beneficial during the early stages of the company’s growth. As the company gains size and recognition, the number of options needed to serve our purpose of course diminishes. Only a small number of options have been exercised, and at October 31, 1962, there were outstanding to key employees options to acquire 85,000 shares during the next five years for a total consideration of $1,080,450. We believe that the number of shares remaining of the 150,000 originally reserved by the shareholders for stock options will be adequate to serve the company’s needs for several years to come. None of the directors have stock options.

Summary — In summary, our second year of operations proceeded substantially in accordance with the company’s original plan. Sales and profits were increased. Our proprietary product base was broadened in both systems and components. Industrial and commercial as well as government business was expanded. We are entering our third year with a record-high backlog in excess of $12,000,000, and we look forward to the further development of Teledyne as a major industrial organization.

1963 Teledyne Shareholder Letter

This report covers your company’s third year of operations. Sales for the year totaled $31,924,685, up 205% from the $10,438,367 of last year. Earnings, net of applicable taxes, were $1,280,296, as compared to $331,518 earned in 1962. Earnings per share advanced 180%, amounting to $1.40 on the 849,461 common shares outstanding at year end.

The company’s financial condition improved substantially during the year. Working capital advanced to more than $9 million, stockholders’ equity to over $8.5 million, and total assets to nearly $24 million. At year end current assets were approximately double current liabilities.

The growth Teledyne is experiencing is being accomplished within the framework of the company’s original plan, and is a direct measure of the progress the company has made toward meeting its fundamental objective. From its inception the company has planned to become a major manufacturer, for industrial and military applications, of electronic and control systems and equipment, and of the specialized components, instruments, and devices that make up such equipment. The steps we have taken in the past have all been in support of this objective.

During the three years since its formation Teledyne has achieved a significant position in the general field of electronic control systems and equipment. In addition to complete systems, we also manufacture and sell separately various subsystems used in automatic control applications. These basic elements include sensors, controllers, actuators and displays. We are producing a variety of sensors or instruments used in control systems to measure the physical quantities being controlled — devices such as probes for measuring temperature, gyros for measuring attitude, instruments for measuring acceleration and velocity, optical and electromagnetic devices for observing position, and others. In the controller area, we are active on computers for fire control, navigation, temperature control, and other purposes. Among the actuators we make for control applications are electric, hydraulic, pneumatic, and in some cases explosive. We have begun to carry out work in the display and read-out area.

We are devoting a substantial effort to our work on communications equipment to link together the elements of control systems, for applications in which the control system elements are separated by considerable distance. For example, our phase-lock tracking receivers carry out this function in the tracking of satellites and space probes.

In addition to our work on control systems as such, we develop and manufacture a substantial amount of equipment used for the check-out of control systems and their elements. Our products in this category cover the range from computer-controlled satellite and space vehicle check-out systems, to equipment to check-out the hydraulic systems of commercial transport aircraft. We manufacture equipment not only to check-out operational systems, but also to test systems during the process of their manufacture.

Teledyne’s interest in electronic and control systems extends beyond the system itself and its major elements discussed above, to include the basic components of the systems. We have established a substantial competence in control system components, and are now producing a variety of electronic, electromechanical, microwave, electro-optical, electro-explosive, hydraulic and pneumatic components — all of which are extensively employed in the systems we produce.

Now operating in twelve plant locations, Teledyne utilizes more than a half-million square feet of engineering and manufacturing floor space. This year saw the addition of plants in Florida and in Arizona, our first plants outside of California. Besides our present owned and leased plant facilities, we have earmarked for new plant construction more than twenty unused acres of company-owned land at three prime industrial locations, and we have options to purchase additional facilities.

While the greatest portion of our effort in 1963 went to support our national defense and space agencies, we continued to make substantial progress towards the development of industrial markets for our products. During the year approximately $5 million, or about 15% of our output, went to industrial customers for industrial and commercial end use.

The outlook for Teledyne is good. Your company has made significant progress in past years, and expects to do so again in 1964. The concern sometimes expressed over shifting defense department procurement policies is not shared by us — we welcome these changes, which favor the more efficient firms. Our participation in industrial markets continues to expand. We are broadly diversified within our area of interest — a field with an unlimited future. We have a strong and dedicated management group, and highly skilled employees. From the base of these advantages, we look to the future with confidence and anticipation.

Review of Operations

Electronic systems and equipment

In Teledyne Systems Corporation we continued our activities in the following fields: computers and data systems, communications, electromagnetic sensors, guidance and control, toxic vapor detection, and integrated electronic and control systems. We also initiated a program in display systems, and expanded our electronic manufacturing and service activities.

Computers and data systems. Preliminary design was completed this year on a digital computer that is triply redundant, modularized by function, and designed such that, in the event of failure in a critical area, the hardware associated with some lesser function automatically replaces that used in the critical area. The logical organization and mechanization of this machine are entirely novel, and result in a great simplification of the programming burden normally associated with digital machinery. The design also achieves truly meaningful modularity, flexibility, and growth capability. Such a computer is practicable by utilizing special microelectronic integrated circuits produced by our Amelco Semiconductor division to provide dramatic increases in piece-part reliability, coupled with great reductions in size, weight, and cost.

Among several other digital programs underway in Teledyne Systems, of particular interest is our advanced high speed digital data recording and analysis system for McDonnell Aircraft, to be used in the ground support system o the Gemini two-man spacecraft.

Work is also proceeding on the POLYLINGUA system, a computer program system to automatically produce translation programs for the problem-oriented programming languages (such as FORTRAN and COBOL) commonly used by programmers. The sale of such translation programs should prove profitable since the computers which now exist as well as those which are under development all need such programs. More important, the theoretical basis of POLYLINGUA system has wide application, and should thus lead to important new strides in a number of related areas. For example, these methods have direct application to the machine translation of languages, and to information retrieval; and they may serve as the basis of a new generation of computers, vastly more efficient in their processing of common problems than previous machines. The theoretical basis of POLYLINGUA is being expanded with these applications in mind.

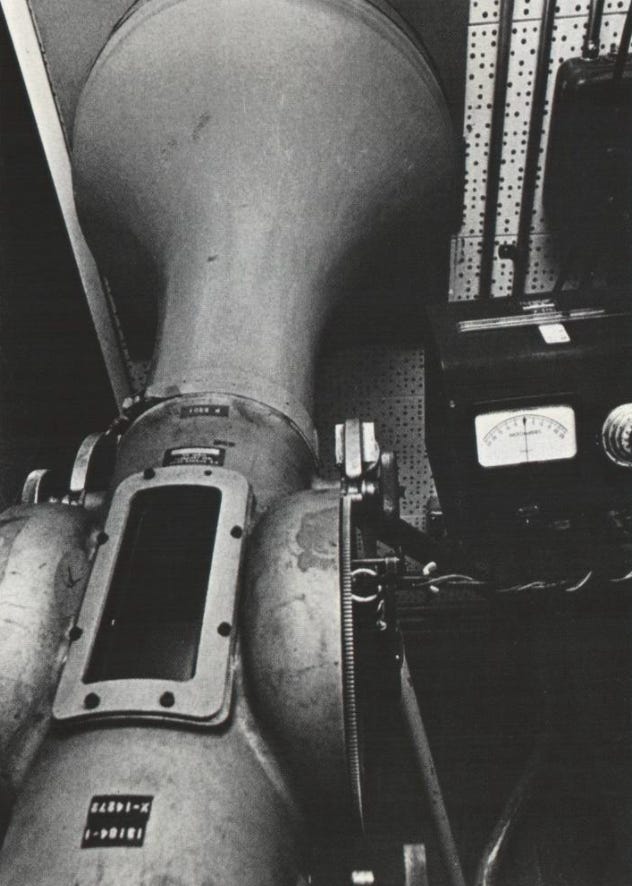

Communications equipment. Teledyne Systems is continuing development of advanced monopulse tracking receivers, after successfully phasing into production this year — our first products of this type. In addition to the expansion of this product line, studies are being performed for the Navy on advanced communication systems requirements for future years. Experimental work is being carried out, directed toward the use of parametric converters in various types of communication equipment.

Electromagnetic sensor systems. Several antenna programs requiring significant advances over existing technology have been undertaken this year for the Navy and Air Force. An example representative of the advanced techniques being employed in antenna systems design is a program for the development of a combination radar and directional IFF antenna for the Navy. The radar portion of the antenna consists of an X-band waveguide slot array with an elliptical aperture. Important advances in array design are represented by the wide operational bandwidth of this array, the absence of azimuth beam squint with frequency, its high power handling capability, its modularized construction, and its extremely light weight. The IFF portion of the antenna is an L-band dipole array which is fed with a unique air-dielectric stripline corporate feed with unusually low loss and good impedance characteristics. Other areas of effort include multiple-beam forming systems, ground based navigation antennas, radar cross section enhancement techniques, as well as general systems analysis in areas of basic propagation phenomena, with emphasis on passive ranging. Production requirements for some of these programs are anticipated in future years.

Guidance and control systems. The development of high-acceleration inertial devices for the Army Missile Command is expanding to accommodate the need for flight test articles. Similarly, development work is continuing for the Air Force’s Aeronautical Systems Division on advanced solid state accelerometers. A program currently in process for the application of microelectronics to gyroscope control circuits shows much promise. Success in this effort would permit the design and integrated inertial navigation systems feature spectacular reductions in over-all size, weight and power.

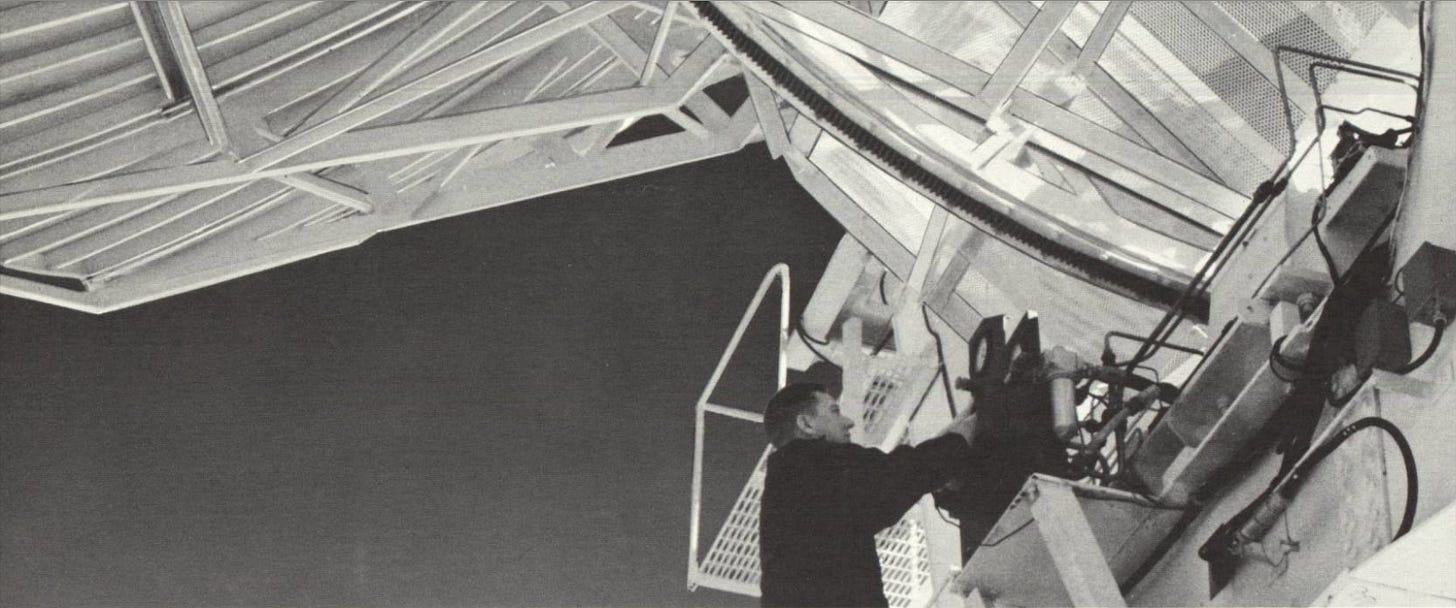

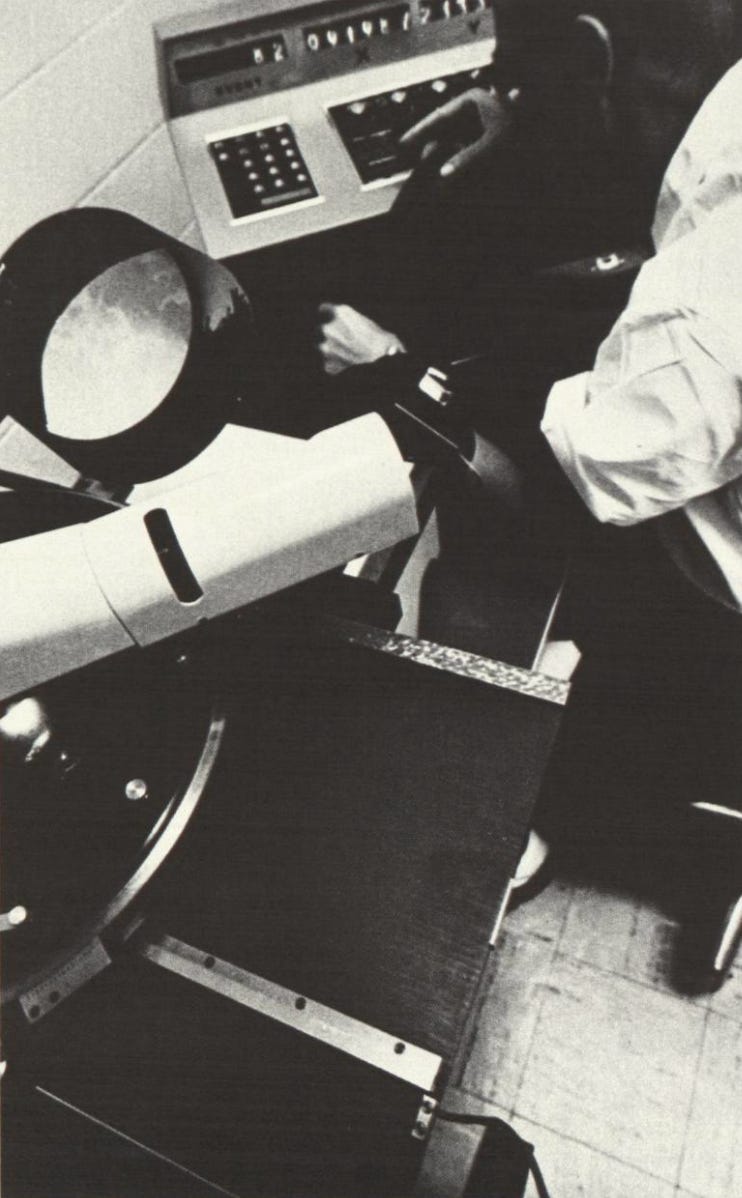

In another aspect of Teledyne’s control system work, 1963 saw the completion of our electronic servo and hydraulic drive systems for Aerospace Corporation’s 15-foot radio telescope and Goldstone Tracking Station’s 30-foot parabolic antenna.Vapor detection systems and devices. Our activity in toxic vapor detection equipment expanded during the year. Teledyne toxic vapor detectors are now in use at Titan missile sites for the detection of nitrogen tetroxide (N2O4) and unsymmetrical dimethyl hydrazine (UDMH) vapors. Toxic vapor detection systems are also being supplied for the Gemini, Apollo and Lunar Excursion Module programs. A new, very lightweight portable detector has been developed and is now in production. A system for the detection of fluorine vapor, a new missile fuel, is currently in development.

Display systems. Early this year we saw the start of our Microeye television project. This project represents the first design effort ever attempted in developing a complete camera system specifically for space application. Starting with the image sensor or vidicon, Teledyne has established the necessary design criteria for a new type of ceramic planar vidicon tube that is fused together into one monolithic structure. This tube is presently under construction in the company’s ultra-clean electron tube laboratory.

The Microeye camera electronics is designed to provide for both internal and external synchronization. The system is capable of accommodating a variety of types of spacecraft telemetry systems, and makes extensive use of microelectronic elements supplied by Teledyne’s semiconductor division.

At present two Government contracts are supporting various phases of this company-originated program. One of these has as its aim the perfection of a system suitable for rocket compartment installation for engine and structure monitoring. The second program is directed toward the problems of human surveillance in the manned capsule.

Integrated systems. Later in the fiscal year Teledyne Systems began a detailed program definition study for the Navy on the Integrated Helicopter Avionics System (IHAS) program. This study makes use of the complete spectrum of our systems capabilities, and further draws heavily on the microelectronics capability of our semiconductor division.

Production programs. The significant advances made during the year in research and development were matched by increasing backlog and increasing shipments of production equipment. We are continuing production of FADAC fire direction computers, and of ARC-73 transmitter-receivers for the Army. With a total of over 7,000 R-390 communications receivers now on order, Teledyne has become the nation’s largest manufacturer of these equipments. The R-390 is utilized by all three branches of the Armed Services. Accepted this year for tri-service use were the M-21 and M-22 reefing line cutters designed and produced by our Ordnance Specialities group. These explosive actuated devices are used to cut parachute shroud lines automatically in air logistic support operations.

Service activities. We continued to provide computer programming services for a variety of applications, and expanded our field service organization for servicing our products in the field. Aerial Control Geotronics, our precision mapping group, operated in nine states this year, rendering services in geodetic engineering, hydrographic and topographic surveying, analytical protogrammetry, missile telemetry, and program development for electronic computation and data reduction. Major customers included the oil, natural gas, electric utility and communications industries, as well as various Government agencies.

Fluid control systems and power equipment

A diversified product line in the fields of hydraulic and pneumatic test equipment and precision electrical power conversion and generating systems were added when Sprague Engineering became a division of Teledyne.

Hydraulic and pneumatic equipment. Extensive product history dating from 1946 has firmly established Sprague Engineering as a major supplier for the aerospace and industrial markets in the field of aircraft service and test equipment. Standard proven proprietary equipment is supplied for system testing and service of hydraulic, pneumatic, refrigeration, supercharger, and other fluid and gas systems. Equipment for test of components prior to installation on new aircraft or after overhaul is provided for aircraft systems utilizing liquids of gases.

Sprague’s industrial product line includes its air-driven hydraulic pumps, supplied in a wide range of output pressures from 100 pounds per square inch to 50,000 pounds per square inch. These pumps are capable of performing many industrial jobs which would be impractical or too expensive by other means. Our air-driven gas booster permits boosting of air, nitrogen or helium to pressures as high as 8,000 pounds per square inch for aircraft and missile test work.

Sprague has been building jet engine starters since 1953. At that time gas turbine starting units were proving to be noisy, undependable, and expensive to maintain. Sprague developed and introduced a new concept using positive displacement blowers, gasoline engine driven. During the following years additional improvements have been made. We believe the current model is the best jet engine starter available. Simplicity; low initial and maintenance costs, and economical fast sure starts characterize Sprague jet starters. Users of various models include most of the major airlines, most of the jet aircraft manufacturers, and several manufacturers of jet engines.

The Magna-Kold compressor, a basic refrigeration unit operating on DC power, is gaining acceptance for boat and trailer refrigeration requirements. This item is also adaptable to a wide variety of uses in other mobile equipment requiring refrigeration units such as trucks, buses, aircraft, trains, and mobile vendors.

Static and Rotary Power Equipment. The Inet Power Equipment Division of Sprague has over many years proven its capability as a supplier of precise high frequency power for a variety of industrial and military ground support applications. A major item in the Inet product line is our brushless synchronous motor-generator set, manufactured in ratings from 1 to 250 KW. The design eliminates the brushes and brush friction, assuring minimum maintenance and trouble-free long life. Inherent in the design is maximum suppression of electronic interference. Unlike magnetic amplifier systems, no excitation power is drawn from the machine terminals, so that the wave form is that which is natural to the generator, a nearly perfect sine wave.

During the year we introduced a line of static frequency converters. The static converter eliminates wear, since it has no moving parts; it is free from noise and mechanical vibration; it gives high performance combined with high reliability and long life; and it permits electronic frequency control. These advantages give the static converter immediate applications to variable speed machine tools and pumps, to controlled speed processes, and to high frequency lighting.

Utilizing the latest semiconductor developments in such areas as high power silicon controlled rectifiers, our design technique has resulted in static converters superior to those previously available. This development is expected to assist materially our planned penetration of the field of industrial process control. With a present producible range of sizes through 6 KVA, significant inroads have been made into this rapidly expanding market.

Microwave components

During the year our proprietary position in precision microwave components was broadened through the acquisition of the Quantatron line. These reliable high speed devices, used for rapid switching of RF and microwave power, employ either a “make-before-break” design, or a unique fail-safe mechanism. Our microwave switches are the smallest and lightest available. They are currently utilized in a variety of operational systems, such as the Hawk and Talos missile systems, and in the airborne radar and communications subsystems employed on the A3J, A5C, and F4H carrier-based aircraft.

Fluid system components

During 1963 Teledyne’s Afco Linair Division became the nation’s leading supplier of hydraulic and pneumatic fittings for aircraft and missiles.

In addition to increasing our proprietary line of standard precision fittings, Afco Linair qualified this year as one of the only two sources approved for the production of MC precision fittings for NASA procurement requirements.

Also this year we completed the development of an entirely new patented type flareless fitting for very high pressure commercial and industrial applications. These fittings, to which we have given the trade name “Flomet”, have successfully passed rigid laboratory tests and have been released for production and sale. The Flomet fitting has a unique close coupling feature — it can be assembled easily, and is capable of operating at twice the internal pressures of equivalent competitive fittings available elsewhere.

To fulfill the stringent requirements imposed by our national space program, we have designed, constructed, and tested a precision tube-flaring machine which furnishes consistent flares in all types of tubes, within the precision tolerances necessary to assure leak-tight joints. Our machine uses a completely new technique in flaring. Flares are produced with measurements accurate to better than a thousandth of an inch. Tubing material that cannot be flared at all using conventional methods, can be quickly and precisely flared using our technique. These machines will be manufactured and introduced for sale in 1964.

Optical systems and components

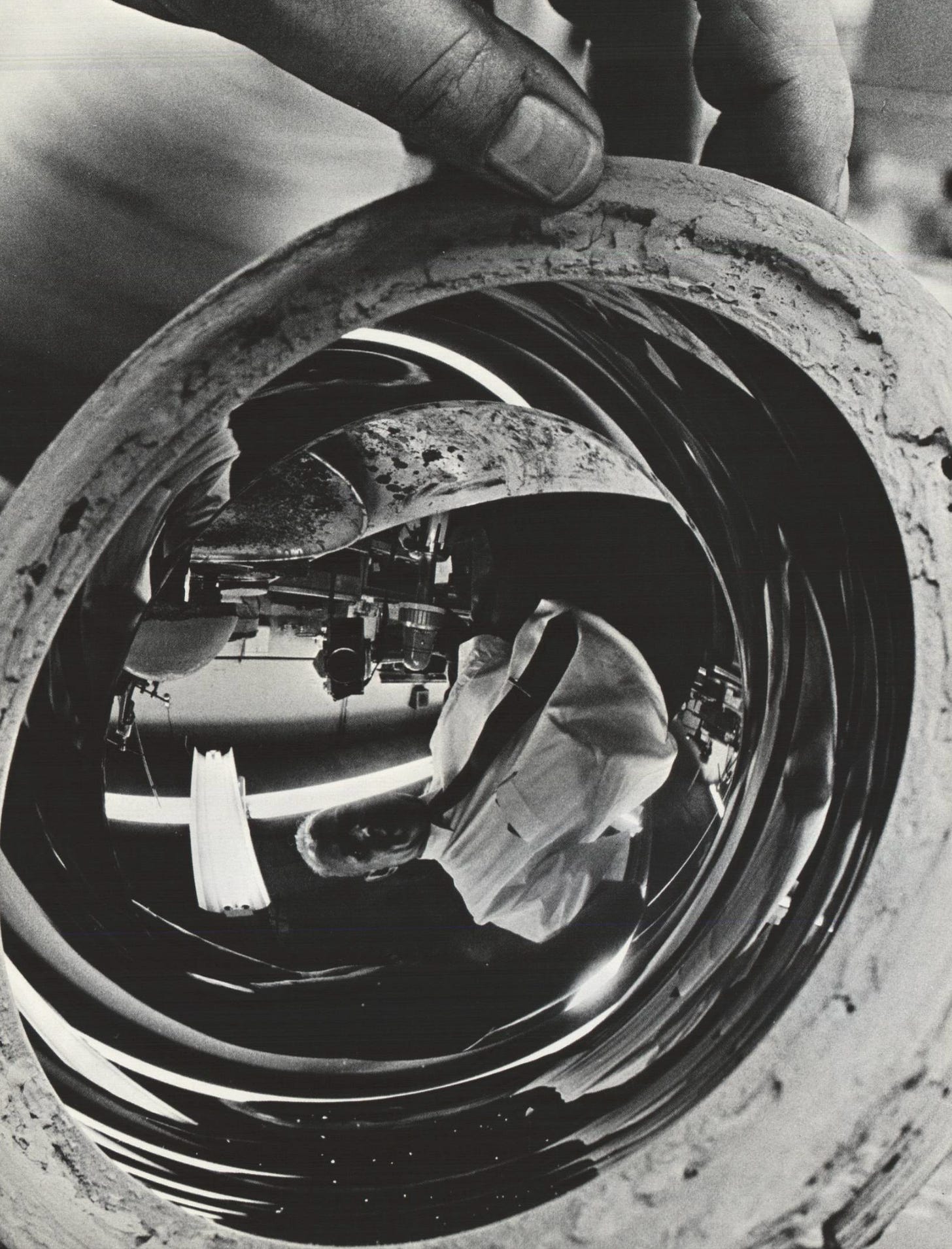

In keeping with our plan of developing know-how in specialized components of significance in electronic systems and equipment, 1963 saw the formation of Teledyne Optics. As the science of optics has been extended from the range of visible light to cover more of the electromagnetic spectrum, the techniques of optical production have grown in complexity and refinement. Teledyne Optics was formed by acquiring and combining three companies with complementary capabilities in development, design, and fabrication of optical components and systems. Typical applications are to automatic navigation devices, tracking cameras and telescopes, observation satellites, visible ultraviolet and infra-red detection systems, and orbiting observatories. The Red Eye, Shillelagh, and Falcon missiles, all heat seekers, employ the Teledyne Optics Irdome, through which the missile sees the target’s infra-red radiation. Teledyne Optics also supplies the lens assembly for an optical character reader employed in a nationally used business machine system. Cylindrical, aspheric, anamorphic and multiple lens elements are fabricated on a regular production basis. In addition to the traditional glasses, Teledyne Optics has wide experience in silicon, sapphire, germanium, arsenic trisulfide, fused silica and strontium titanate. A cooperative program, involving the joint efforts of Teledyne Optics and Teledyne Systems, is planned for the application of their combined know-how to advance electro-optical systems.

Electronic components

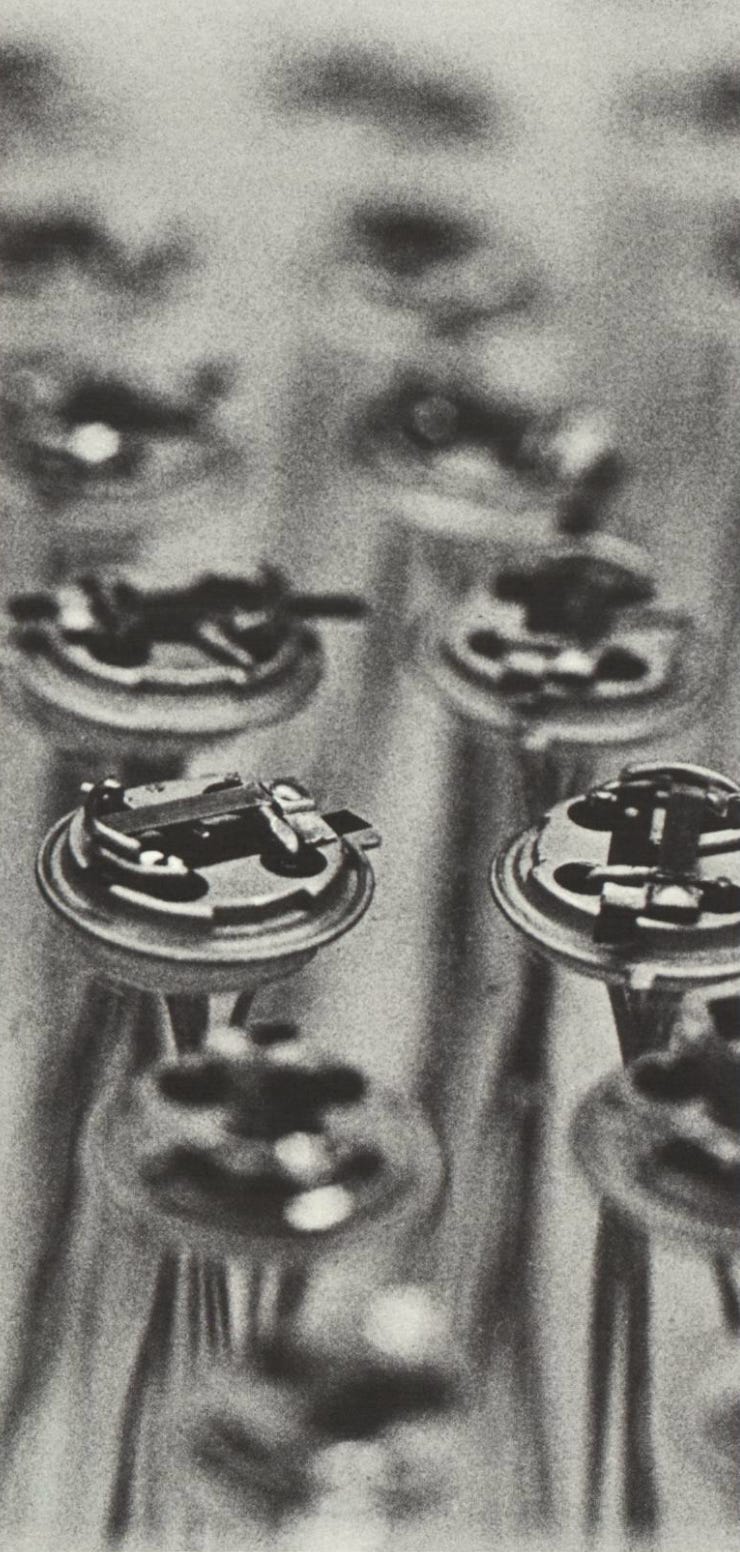

Teledyne Precision, Inc. continued to extend its product line during the year — a line that now includes relays, potentiometers, switches, quartz crystals, temperature controlled component enclosures, thermal probes and temperature sensing devices, temperature oriented control and test equipment, and military and commercial slip ring and brush assemblies. The acquisition of Control Dynamics Corporation complemented TPI’s sub-miniature electro-mechanical relay business by adding a line of full and half-size crystal can relays, plus a number of different designs of microminiature types.

The addition of Electro Development Company enhanced our switch business and established us as a supplier of high quality slip ring assemblies. Electro Development originated the hot pressure molded method of manufacturing military and commercial slip ring and brush assemblies. Our slip rings are widely used to transfer electrical power and signals between structures rotating relative to each other, as in synchros, gyros, and various navigational devices.

In the area of more complex devices, Teledyne Precision has under development for the Martin-Marietta Company a 100-pole double-throw switch to be used for relaying telemetry signals from the Titan III missile. Each of these complex switches utilizes 100 of our ultra-miniature TO-5 relays.

Semiconductor devices and integrated circuits

The business of our Amelco Semiconductor Division may be separated into four specialized categories of proprietary products: advanced silicon planar transistors; differential amplifiers, and other special assemblies of discrete devices; integrated circuits; and field effect transistors. These products were selected because the high degree of technology currently required for their production allows us to compete effectively with other larger suppliers, and because we believe these products will eventually account for the majority of semiconductor production.

During the year our position in each of these product categories continued to improve, and we introduced to the market several new products in each area. We have become a major supplier of differential amplifiers, and our field effect transistors are, we believe, more widely used than those of any other supplier. We expect the use of field effect devices to increase very rapidly as they become better known and more generally available to the electronic circuit designer. Now utilized primarily in military applications, large industrial markets should open up as the production cost of these devices is brought into line with those of conventional transistors.

I field of integrated digital microcircuits our OMIC (optimized microcircuits) line was recently introduced. This line, in which the transistor design and interconnections have been developed from the viewpoint of the particular circuit application, numbers twelve basic logic circuits and is now being shipped from stock in production quantities.

During the year Amelco Semiconductor has continued to cooperate closely with Teledyne Systems on a variety of projects. Among these is circuit design work on the IHAS program, development of microelectronic circuits for the Microeye miniature vidicon, and the development of very low power integrated logic elements aimed at high component density systems for space applications.

1964 Teledyne Shareholder Letter

As it has each year since its inception, in fiscal 1964 your company again achieved record sales and earnings. New highs were also recorded in orders booked, number of people employed, amount of plant space utilized, and other measures of business activity. Sales were up 20 per cent to $38,187,127. Net earnings for the year increased to $2,545,388, a gain of 98 per cent over the $1,280,296 reported for 1963. Earnings per share advanced to $2.35, a 68 per cent increase over last year’s $1.40.

At year end Teledyne’s financial condition was the strongest in the company’s history. During the year working capital increased 54 per cent to $14.2 million, stockholders’ equity advanced 58 per cent to $13.7 million and total assets increased 46 per cent to $35.0 million. The ratio of current assets to current liabilities was 2.4 to 1.

Even more important than the gain in operating results was the progress made during the year in broadening and strengthening the company’s foundation for future growth. Our product base was expanded; plant facilities and equipment were increased and improved; industrial and commercial activity was stepped up; and several important acquisitions were made.

Substantial additions were made to plant facilities, with the amount of floor space in use increasing 30 per cent to a total of 650,000 square feet at year end. New production and test equipment was added throughout the company, and we continued our program of upgrading and modernizing existing machinery. Book value of company-owned facilities rose to over $7 million, a gain of 40 per cent over last year.

Teledyne’s fundamental dedication to the field of automatic control systems, equipment, and components was exemplified by the broadening of the company’s product base that took place during the year. The products in this field, including sensors, computers, actuators, displays, and communications links, are characterized by a high rate of technological obsolescence, and dictate a strong dependence on technical innovation and leadership. Your company continued to invest heavily in research and development throughout the year. As a result many new products were introduced, ranging from highly advanced integrated analog circuits to jet engine starting systems. Additional new products are under development, and scheduled for introduction in future years. Balancing our internal product development program is our systematic addition of selected products through acquisition. This year acquisition brought us such important new products as communications equipment, explosively actuated devices and aircraft display equipment.

Our participation in industrial and commercial markets continued to grow. Non-Government shipments approximated $7 million, a 40 per cent increase over last year. Subsequent to year end we further increased our industrial product base through the addition of Pacific Industrial Controls and Analytics Systems Company, acquired as part of United ElectroDynamics. The products of these two divisions, used throughout the nation for a broad range of automatic control applications, considerably enhance our position in the general field of industrial process control. Because of the prospective future growth in the industrial applications of electronic control equipment, we are proceeding with a vigorous program of further development in this area.

Subsequent to fiscal year end Teledyne acquired the business and assets of Servomechanisms, Inc. SMI has been active for many years in the development and production of aircraft flight instruments, being particularly well known for its air data computer systems. SMI’s capabilities complement our existing activities in flight control and instrumentation. Because of our conviction that air data instruments will be of growing importance as our airways become more crowded, we place a high valuation on the long-term importance of the SMI acquisition.

Also shortly after year end United ElectroDynamics, Inc. was acquired and consolidated with Teledyne. UED’s activities, other than the industrial controls business mentioned above, include airborne telemetry and seismic equipment and services. Through the UED acquisition we have taken a place among the leaders in these two fields, both of which are compatible with our present activities and long-range interests.

The product area of automatic control equipment is one of unlimited promise. If properly developed and wisely employed, machines have the ultimate capability to free man from labor, and to extend indefinitely the range of his intellect. It is our privilege at Teledyne to have achieved a strong position in this field of limitless opportunity. We are confident that our efforts will result in further progress in the years ahead.

Review of operations

Electronic systems and equipment

Computers and data systems

Progress continued this year on the detailed design of Teledyne’s unique new family of digital computers. The machines are potentially applicable to a broad range of real time control system requirements, where the modular design of the computers permits them to be precisely tailored to the intended application. Combining the simple functional organization and high speed response of analog computers with the accuracy and logical capabilities of digital computers, the machines make use of a combination of incremental and whole number computing techniques. Very little programming is required. Through the use of majority logic and built-in failure detection and isolation circuits which initiate automatic self-reconfiguration to bypass any failed element, virtually failure-proof operation is assured. The microelectronic integrated circuit modules utilized in the computer are produced by our Amelco Semiconductor division.

Work on several other important digital computer projects was carried forward this year. Among systems completed and delivered in 1964 was an advanced Loran A & C Digital Simulator developed for the Federal Aviation Agency utilizing a magnetic tape-stored position program. The simulator provides a real time input to the Loran receiver system under evaluation. It precisely simulates characteristics that are normally encountered in actual flight conditions, including aircraft velocity, rate of turn, ground-wave, sky-wave, coding, and doppler effects among others.

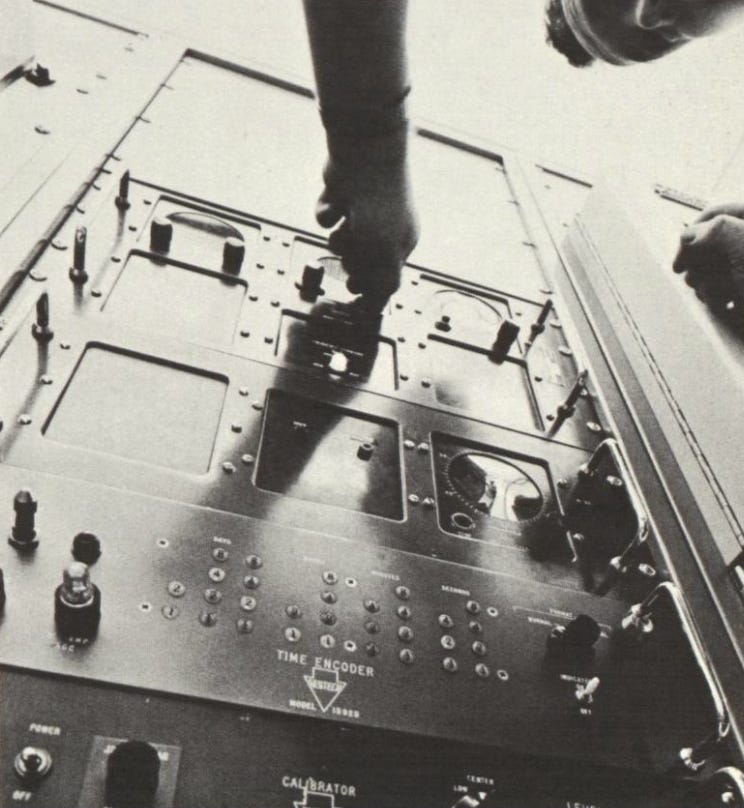

This year also marked delivery of the Computer Data Recording System to McDonnell Aircraft Corporation for use in the pre-launch checkout complex for the Gemini program. The equipment is currently installed at Cape Kennedy, and has been utilized in the successful test launches of Gemini Capsules I and II. Production also continued throughout 1964 on the FADAC fire detection computers for the army.

Final development is under way on the POLYLINGUA system, a computer program system to produce automatically translation programs for the special languages (such as FORTRAN and COBOL) commonly used by programmers. This system uses highly advanced techniques including a new theoretical model for language syntax. As a result, the translation programs which it produces are very competitive with respect to speed, and can be operated in all but the smallest computers. This programming system significantly advances the art of translation program production. Such programs can be automatically produced for any programming language, and for almost any computer.

Communications and antenna systems

The past year has seen a continued growth in the company’s activities in communications and antenna systems and related technologies. An outstanding new program is for the design, fabrication, and delivery of a feed subsystem for use on a 60-foot Casegrain reflector antenna. The system is being built for Navy/NASA satellite tracking applications, and will permit simultaneous operation at both L and X band frequencies. It will also provide a choice of either monopulse or conical-scan tracking. The same NASA/Navy system has led to a development program for a complete receiving subsystem to provide compatible operation with the feed subsystem. The receiving subsystem utilizes Teledyne’s monopulse tracking receiver in conjunction with a specially designed down-conversion unit to achieve high stability operation at UHF, L-band and X-band frequencies. As part of this unit, Teledyne is developing a step-recovery diode multiplier, the completion of which will materially strengthen our integrated systems capability.

Directly related to our existing capability in antenna systems is our continuing development of parametric amplifiers and broadband mixers. This product line is based on proprietary design techniques which permit achievement of large gain-bandwidth products and extremely low noise figures. With the addition of this capability, Teledyne is now prepared to offer complete receiving systems for low noise applications in telemetry tracking, satellite communications, and radar target location.

For several years Teledyne has pioneered in exploring techniques for microwave passive ranging utilizing a proprietary design concept. Recent studies performed for the Navy has culminated in the completion of an experimental system to verify the operational feasibility of the approach. The experimental equipment is currently undergoing flight tests under Navy sponsorship. Completion of this phase of the program is expected to lead to development of service test models and subsequent production.

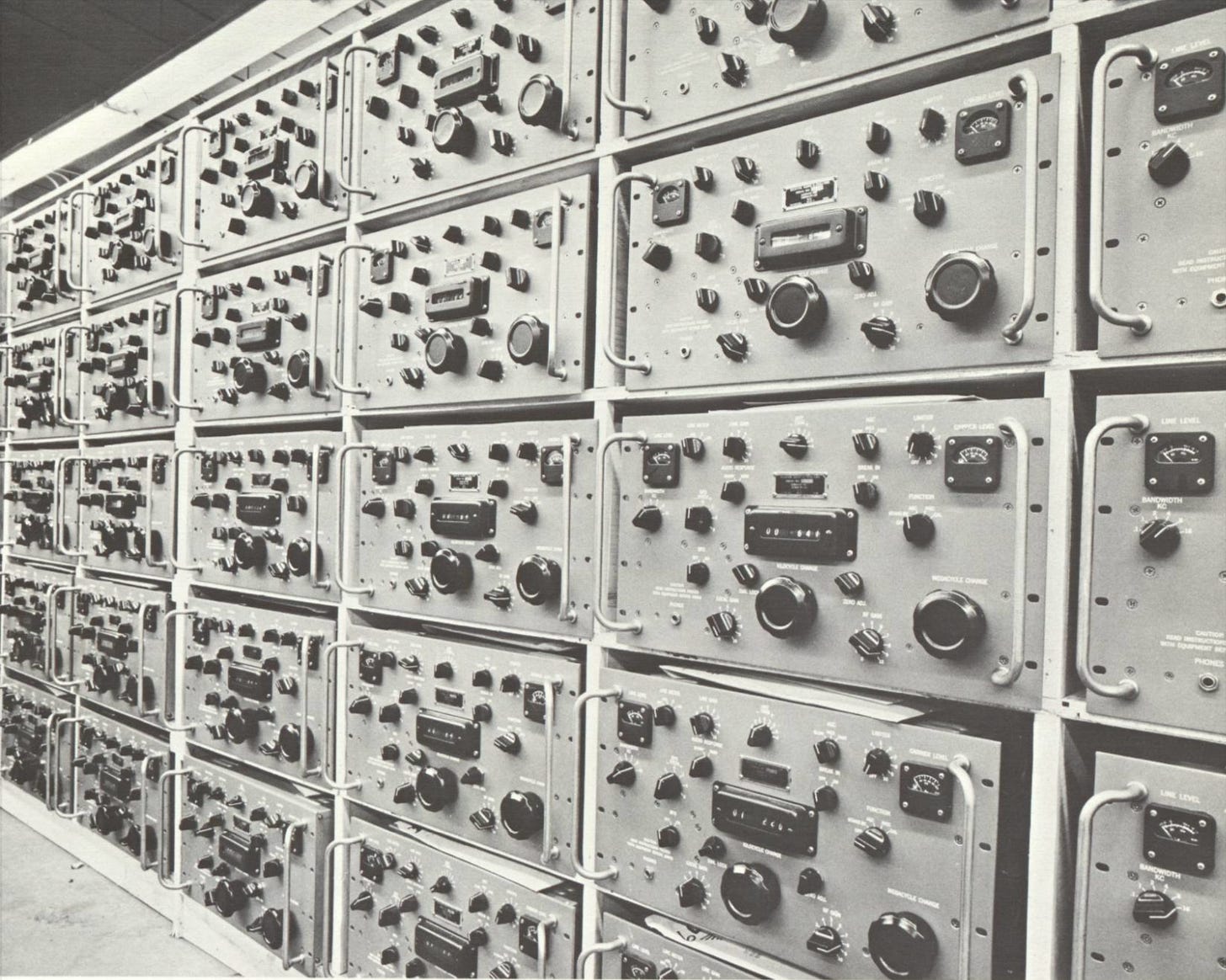

Progress in production of communications equipment matched that achieved in research and development. Production of R-390 receivers, ARC-73 UHF transceivers and monopulse tracking receivers has continued, and further improvement in manufacturing efficiency has been achieved by the use of automated production techniques. Chassis and subsystem flow is controlled by motor-driven conveyor belts which position cycle between work stations in accordance with optimum time standards for each assembly operation. In addition, our machine shop facilities have been expanded to provide improved production support.

Dubrow Electronics, our production organization in Burlington, New Jersey, continued shipment of UPA-35 radar display consoles, and began production of GRC-19 communication sets. The addition of Dubrow Electronics has strengthened our over-all manufacturing capability, and gives us a greater degree of flexibility in making best use of our specialized talents in electronic assembly and fabrication.

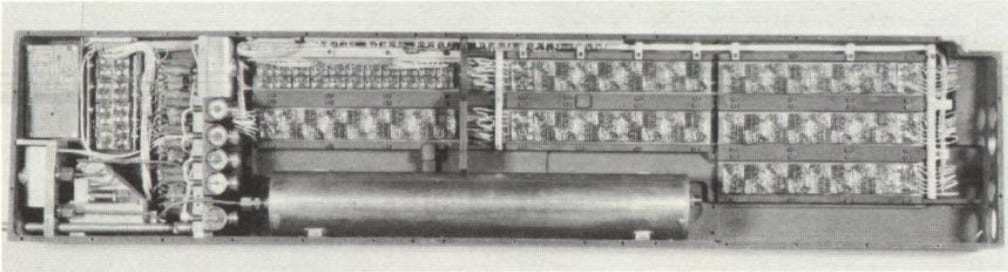

Airborne telemetry systems

With the acquisition of United ElectroDynamics shortly after year end, Teledyne became one of the nation’s foremost suppliers of airborne telemetry equipment. In 1956 UED made the first application of solid state circuity to airborne telemetry in the Sergeant missile program, and since that time has been a leader in advancing the technology of airborne telemetry.

In 1964 UED was an important supplier of telemetry components and systems on several major programs. UED supplied both the RF links and the analog modulation systems for all operational test flights of the Minuteman intercontinental ballistic missile. Another major contribution was the continued supply of PAM/FM/FM telemetry systems to the Ballistic System Division of the Air Force for use on every operational training flight of the Atlas, Titan, and Thor missiles flown from Vandenberg Air Force Base.

In applications to manned space flight, 1964 saw development of the signal conditioning amplifiers which constitute the backbone of the telecommunications signal conditioning subsystem of the Apollo spacecraft. Production of the prototype hardware was completed, and production was started on flight units. We will continue production of Apollo spacecraft signal conditioning amplifiers during the first half of the year, and we anticipate continuing participation in the upcoming second Block II phase of the Apollo program.

Also in 1964 UED designed, qualified and delivered the pulse code modulation telemetry systems for use in NASA’s micro-meteoroid satellite (Pegasus). This program was followed by the design of an extremely flexible 80-800 channel high and low-level PCM system for use in the NASA Flight Research Center Lunar Landing Research Vehicle, and UED continued to supply a unique d-c amplifier for each Agena missile. A further contribution to the space effort is UED’s PCM RF transmitter system utilized by several prime contractors in various phases of the Saturn program.

Other projects include the development and production of an advanced telemetry system for ARPA’s Hibex (High Environmental Booster Experiment) missile. This system successfully performed through environmental conditions more severe than those sustained by any previous missile system. In support of the Navy’s Shrike missile program, UED designed, qualified and manufactured a substantial quantity of battery-operated PDM FM/FM telemetry systems. We have recently gone through the first successful firing of a new telemetry system for the Army’s medium anti-tank weapon, and follow-on production is anticipated.

Substantial progress is being made in research and development of solid state telemetry transmitters and oscillators—work being concentrated in the UHF region and in increasing the RF power level in the VHF spectrum. Advances are also being made in oscillator linearity and reliability. Development activity in 1964 produced a low-level commutator and an analog-to-digital converter for use in advanced PCM systems.

UED has developed and installed the telemetry communications systems for Standard Oil Company of California which link the offshore oil well platform at Ventura with the onshore operations office, and similar equipment was installed in Standard’s remote Alaskan fields.

Currently we have booked, or are in the process of negotiating, substantial continuing contracts on the Minuteman, Agena, and Saturn missile programs, as well as two classified Atomic Energy Commission programs. It is anticipated that these programs will continue throughout 1965. Also, 1965 will see production of an advanced state-of-the-art pulsed RF amplifier system for use by the AEC on a classified test program requiring substantial follow-on production.

Instrument and control systems

This year Teledyne began development of a low-cost Flight Reference Stabilization System (FRSS) for the Air Force’s Aeronautical Systems Division. The FRSS is intended for application as a flight reference device to a wide variety of aircraft and space vehicles. In addition to its low cost, this advanced system features minimum size, weight, and power consumption. The FRSS is potentially a large production item for future years. Completion of design, fabrication, and testing of the first models of the system is scheduled for next year.

Development work on inertial devices for the Army Missile Command was continued this year and work is proceeding on the fabrication of flight test units. These devices include a high-acceleration angular-rate measuring instrument, and a free rotor gyroscope that utilizes new concepts to supplement existing technology. We are also developing miniature precision accelerometers for the Air Force and the Navy.

Shortly after the close of the fiscal year, Teledyne expanded its position in the flight instrument field through the acquisition of Servomechanisms, Inc. SMI has been a major factor in the development of air data devices and systems. Air data information, a basic requirement for precision flight control of airborne vehicles, is of growing importance as the number of aircraft in use continues to increase.

During the year SMI completed the development and production design of a lightweight central air data computer for the Douglas A4E Skyhawk attack aircraft. The initial production order for this Navy aircraft is currently nearing completion, and a follow-on order has been received. An additional production order is expected in fiscal 1966, and should extend the program over a period of several years.

We are also supplying the air data computer for the A7A (VAL) aircraft. The design and development, under contract with Ling-Temco-Vought, was carried out this year, and an initial production order has been received. The first unit has been delivered and the second unit, which will be utilized for qualification, is near final test stage. The delivery of the initial production units extends into early 1966, and we are anticipating a substantial follow-on production order in that same year. The A7A (VAL) aircraft is programmed for heavy production for the next several years.

Another contract with Ling-Temco-Vought calls for design and development of a true airspeed computer for utilization on the RF8G aircraft. The initial production order is for some 50 units with delivery commencing in April 1965. Additional purchases are expected in the next fiscal year.

In addition to air data systems, SMI develops and manufactures the pressure transducers which provide the basic inputs to the air data computer. The division also supplies separate pressure transducers for a variety of applications. Many of our transducers are manufactured for NASA and are used on various space programs.

An important adjunct of the air data system is the angle of attack transmitter, or vane. SMI is a leading manufacturer of these precision devices, which detect local air flow and produce an electrical output proportional to the angle between the local airstream and an aircraft reference line. This year SMI qualified its universal vane for the Air Force, and we have just received an award from the Air Force Systems Command for several hundred production units under a multi-year procurement. We are currently providing vanes for the A4E, the F8E, and the A7A (VAL) aircraft, all for the U.S. Navy. Our angle of attack transmitter is also being used on the F-104, on the French Dassault Mirage fighter, and on the new Lear Jet executive aircraft.

The SMI ice detector units have been selected for the F-111 (TFX). The ice sensing mechanism is entirely mechanical and does not rely on any change of pneumatic pressures for its operation, and thus, is not affected by rain or dirt contamination. The independence from pneumatic pressures assures dependable icing indications at all speeds or even when the aircraft is on the ground. For helicopter or VTOL applications this becomes an added advantage since it permits the reliable indication of icing when the aircraft is hovering.

The SMI thermocouple reference junction compensator is receiving wide acceptance. This device electrically compensates for reference junction variations in a thermocouple temperature measurement system. We are supplying compensators for use on the Titan III program, the Minuteman program, and the Apollo Lunar Excursion Module.

Earth sciences

Teledyne’s entrance into the field of earth sciences was accomplished through the acquisition of United ElectroDynamics. We thus acquired an organization with an established capability in detecting, measuring, and evaluating earth movements. Major improvements in seismology have come about in recent years as a result of the 1958 Geneva Conference, which sought to establish specifications and methods for nuclear test detection. Our earth sciences organization has led in these improvements, and has been a prime contractor on project Vela since 1960. As part of the Vela program, the Earth Sciences division established the Tonto Forest Seismological Observatory, selecting the remote Payson, Arizona site because of the low level of microseismic earth vibration, after detailed study of 53 possible locations throughout the nation. Earth Sciences designed, fabricated, tested and installed the equipment under the direction of the Advanced Research Projects Agency with technical supervision provided by the USAF Technical Applications Center.

The Tonto Observatory monitors and records earth vibrations from more than 80 seismometers of various types, buried in the ground in vaults. A large number of these seismometers are placed in both linear and symmetrical array patters on 23,000 acres of Tonto National Forest. Each seismometer measures movement in the earth smaller than a ten-millionth of an inch. Twenty miles of trails and 525 miles of electrical cable connect the seismometers with the recording and control center. The control center records the seismic motions, and the records are forwarded to our Seismic Data Laboratory in Alexandria, Virginia, for evaluation and analysis. At the laboratory our scientists evaluate the information from Tonto Forest, as well as other seismic information supplied by a vast network of fixed and mobile recording stations, integrating and analyzing the many diverse seismic techniques to improve underground explosion detection methods. We are operating the Seismic Data Laboratory for the USAF Technical Applications Center as part of ARPA’s Vela Uniform project.

Subsequent to fiscal year end we were awarded a significant contract related to the Vela Uniform project which involves the installation and checkout of the world’s largest seismic array. The work is being performed in the eastern half of the state of Montana and covers a large portion of the state. Some 500 of our seismometers and amplifiers are being installed in holes drilled, cased, and cemented by our crews.

Earth Sciences recently became active in lunar and planetary sciences by teaming with Bendix Systems Division to submit a winning proposal to NASA Headquarters. Our portion of the program requires an extensive study of the potential experiments to be performed by the Apollo astronauts when they reach the surface of the moon. Various types of geophysical information will be obtained by means and instrumentation to be specified for this program as a result of the study. Hardware development in this area is expected to follow our present study program.

Integrated avionics systems

The Program Definition Phase for the Integrated Helicopter Avionics System (IHAS) has been successfully completed. Our report has been submitted to the Navy and preliminary negotiations are proceeding for the award of a prime contract to Teledyne to develop and supply the complete system. The initial operational application of the IHAS planned by the Navy is in the CH-53A assault helicopter for the Marine Corps; however, the high degree of modularity and flexibility achieved in the system design has led to the contemplation by the Services of the use of the IHAS in a number of other fixed and rotary wing aircraft as well. The planned broad usage of the IHAS has both Army and Navy, in various aircraft, is consonance with current Department of Defense emphasis on commonality to provide maximum capability per dollar, especially in new developments offering major improvements in system effectiveness.

As an outgrowth of experience gained on the IHAS program, Teledyne has been awarded a contract to study the avionics system requirements for the Army’s Advanced Aerial Fire Support System (AAFSS). This effort requires an extensive study of the fire control problems associated with a variety of weapons as well as computational and system problems pertaining to the over-all requirements. Paramount in this study, as in others, is the accurate and objective assessment of the cost effectiveness of the proposed system.

Recognizing the importance of the cost effectiveness concept in defense planning, we have developed, for use on large-scale computers, a generalized mathematical model which has proven to be a powerful tool in the evaluation and optimization of defense systems. We foresee continuing emphasis on the requirement for rigorous validation of planned systems from a cost effectiveness standpoint. By virtue of our considerable and early experience in this field we anticipate further growth of our activities in this area.

Industrial and support equipment

Analytic systems

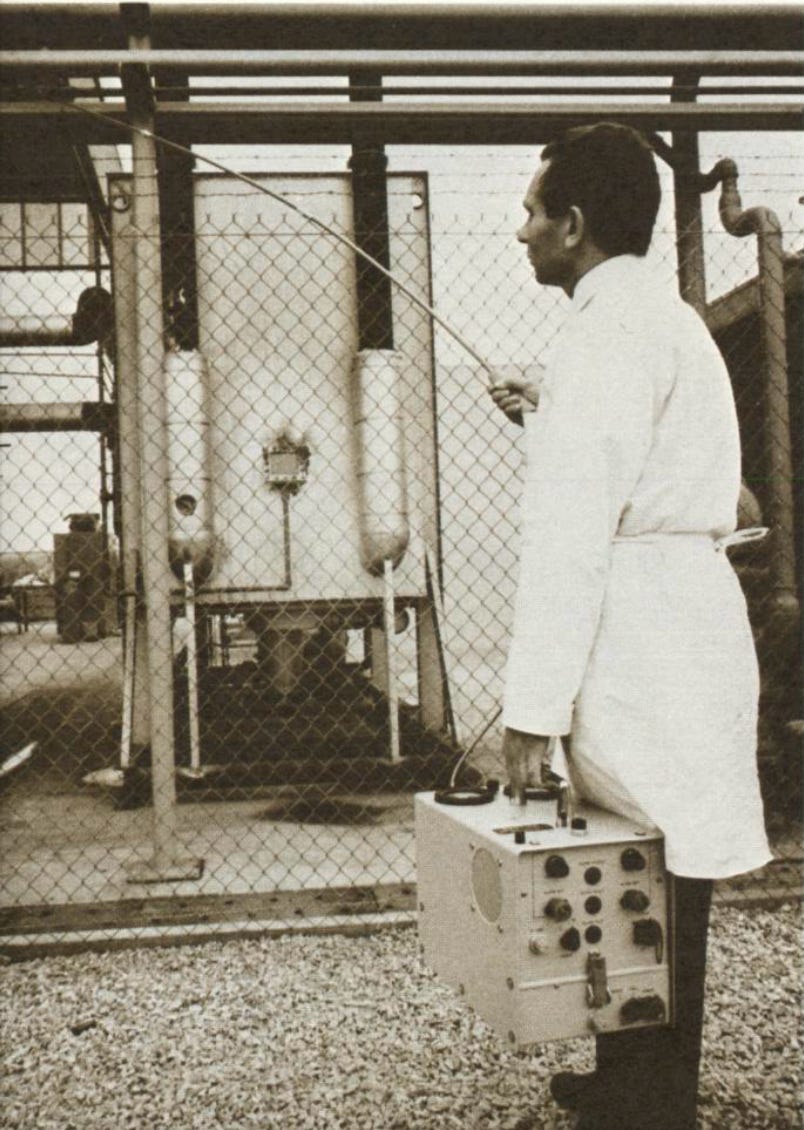

Our analytical systems product line includes eight major types of gas and liquid analyzers applied generally in the petroleum, petrochemical, and chemical industries for on stream process analysis and control. The business is conducted through our Analytic Systems division, acquired shortly after year end as part of United ElectroDynamics.

The eight major types of analyzers can be classified into three main groups. The first group is composed of gas analyzers that include thermal conductivity, trace and per cent oxygen, flame ionization (hydrocarbons) and combustibles monitors. These instruments are used to measure the purity of, and the impurities in, various gas streams, with the majority of applications being in the air liquefaction industry. A less common application now being encountered with increasing frequency is to inert gas generators, where it is necessary to measure both total combustibles and trace oxygen. Other applications relate to secondary recovery in oil fields and to process control in plastic plants. In the latter case, traces of oxygen may change the color and properties of plastics, causing a loss of product and increased operating costs.

The second group of products consists of the near infrared, ultraviolet and infrared photometric analyzers. Here the main applications are centered around needs in the petroleum and petrochemical industries, but recent emphasis has been placed on other chemical industry applications, such as plastics production and fertilizer plant controls. One of the more critical applications of this group of instruments is their use in detecting toxic vapors, such as hydrogen sulfide and mercury vapor. The latter measurement is particularly important in industries where the use of mercury vapor lamps and large amounts of liquid mercury can pose a health hazard to personnel.

The gas chromatograph family of instruments is the newest addition to Analytic Systems product line. Process control gas chromatography was chiefly developed for the petroleum industry. This means of analysis and control also has great promise as a support method for nearly all of the applications previously mentioned for Analytic Systems’ other instruments. The market for process chromatography is expected to increase rapidly and we are planning to expand our activity in this field.

Pacific industrial controls

Our Pacific Industrial Controls division was also brought into Teledyne through the United ElectroDynamics acquisition. PIC manufactures more than 50 different models of pre-packaged controls which automate equipment and conveyor systems by automatically stopping, starting, reversing and changing operating speeds of electric motors. Through PIC we are rapidly becoming an important supplier of such controls. Marketed under the trade name of “Ratiotrol” and “Precision Speed Regulator,” PIC’s controls are designed to be merchandised as off-the-shelf packages by power transmission products dealers and distributors. The automating controls manufactured by PIC are marketed through the Boston Gear Works of Quincy, Massachusetts, the largest manufacturer and distributor of power transmission products in the United States.

PIC is also introducing an automated clutch and braking device for use on small (up to 20 horsepower) electric motors.

Power equipment

In our Inet division we continued this year to expand the use of our brushless synchronous motor-generator set, manufactured in ratings from 1 to 250KW. A commercial version of this equipment is used by major airlines at terminals throughout the United States. Another product development for airline ground service, and in use in the United States and overseas, is our truck-mounted, 140 KVA, 400 cycle diesel engine generator set complete with all necessary controls.

During 1964 Teledyne began supplying precise static d-c power equipment for the Apollo and Saturn programs. This development has provided a new family of SCR regulated, high current (50 to 500 ampere) d-c power supplies suitable for the most critical system requirements. Exceptional performance and reliability are achieved through the use of high power silicon controlled rectifiers and solid state overvoltage, undervoltage and overcurrent protective devices mounted on plug-in printed circuit boards.

Also this year, shipments were made against an Air Force contract on a new line of static power conversion equipment to be used on USAF Mobile Training Units for the C-141, C-130 and C-133 aircraft.

Another development of particular interest this year was the introduction of our Inet Transient Synthesizer (ITS). To be used for testing communications equipment, the ITS generates a full family of voltage and frequency transients which are programmed and recorded on the Synthesizer Visicorder. The Synthesizer consists of an SCR inverter, programmed by solid state devices, as the controllable sine wave power source; a surge generator for supplying simulated lightning and switching surges; and suitable instrumentation for indicating and recording the pertinent electrical transient phenomena. The ITS is fully portable, and is built in five separate modules, so that the size and weight of any one module is no greater than that of a large household application. This allows for easy transportability in order to permit use of the equipment for studying specific performance characteristics of critical communication loads at widely dispersed sites.

Sprague division

In 1964 Teledyne’s Sprague Engineering division maintained its position as the industry’s standard in aircraft hydraulic and pneumatic equipment. The Sprague line of mobile jet engine starters, in use for many years throughout the world, was supplemented this year by the introduction of a pneumatic jet engine starting system, for permanent facility installation. Used at new jet air terminals and for air terminal modernization programs, the starting equipment is located in a permanent installation in the utility area of the air terminal. From the utility area the compressed air is piped underground to as many starting pads as red.

In support of the manned space flight program we were selected by the Boeing Airplane Company to supply the remote control pumping system for testing the servoactuators on the Saturn V rocket engine. Our proven ability to handle systems for contaminant-free liquids under high pressures was a major factor in obtaining this program.

In another development this year, Sprague Engineering built and delivered its first hydrofoil passenger boat. Now in use at Sea World Marine Park in San Diego, this 34-foot excursion craft is the only hydrofoil operating on the West Coast which is Coast Guard approved for carrying passengers. A total of three of these hydrofoil boats have been delivered. We have also contracted with the Coast Guard to install a set of foils on one of their 30-foot patrol boats.

Following the success of the Sea World hydrofoils, we have begun construction of two 58-foot seventy passenger hydrofoil ferrycraft for the Woods Hole, Martha’s Vineyard and Nantucket Steamship Authority of Massachusetts. To be utilized for scheduled ferry service, it is expected that these hydrofoils will operate at approximately 40 knots, reducing travel time to about 25 per cent of its present value.

Instrumentation and components

Electronic components

During the year our precision components division placed special emphasis on advanced rotary and rectilinear switch assemblies for use in liquid oxygen and gaseous oxygen rocket engine fueling systems. Units of this type are being supplied for the Rocketdyne F1 and J2 rocket engines. These switches fully meet the stringent reliability requirements dictated by NASA Saturn specifications.

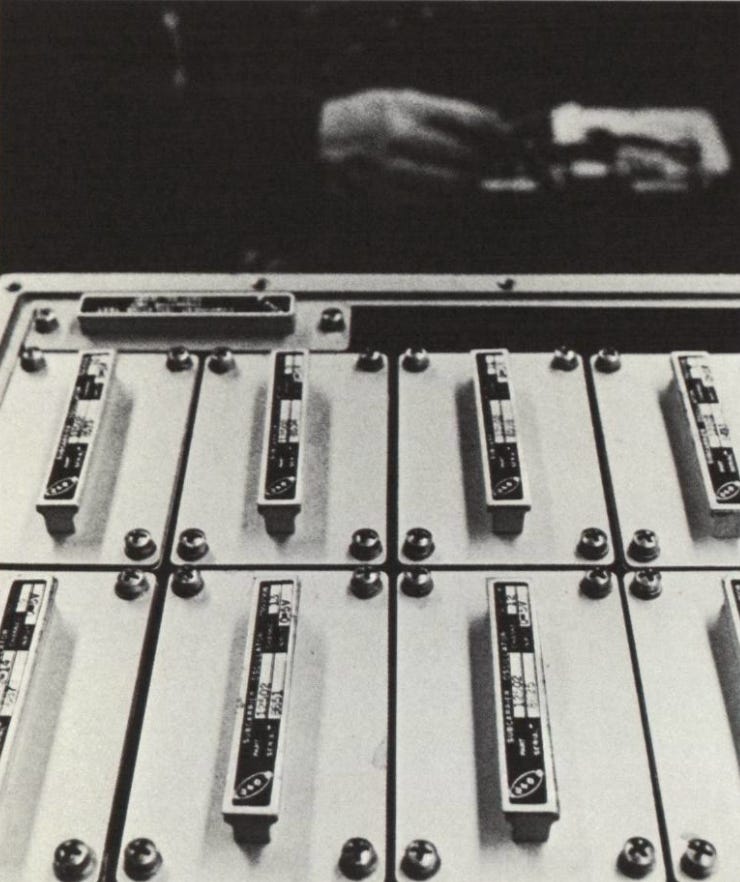

During 1964 we completed qualification and shipped production quantities of our 100-pole, double-throw switch. We developed this switch for The Martin Company for use on the Titan III missile as a telemetry signal transfer switch. Each of the more than 40 switches shipped contains 100 of Teledyne’s ultraminiature TO-5 relays.

We are continuing to expand our TO-5 relay manufacturing capability. To broaden the TO-5 product line, we have recently introduced two additional TO-5 configurations: a magnetic latching version, and a 40 milliwatt ultrasensitive model. Development is also near completion on a double-pole double-throw TO-5 relay. The TO-5 relays remain the smallest available, and with the increased number of models available constitute the industry’s broadest line in the ultraminiature class.

The Mechatrol line of synchronous motors, servo motors, gearhead motors and metal film potentiometers acquired in November 1964 further enlarged our activity in the components field. Typical users of Mechatrol components include the Atlas, Pershing, Polaris and Titan missiles; the B-52, B-58, F-104, F-105, F-106 and F-110 aircaft; and the Discoverer, Tiros and other space vehicles.

Optical components

Teledyne Optics’ first full year of operation since its formation in 1963 showed good progress. The division now has the largest infrared optics manufacturing and test capability in the western United States. Teledyne’s infrared optics are utilized in most of our armed forces’ arsenal of heat seeking missiles. Development work for the Ford Motor Company’s Aeroneutronics division on the optical requirements for the Shillelagh missile was completed late this year, and it is anticipated that production requirements will be released in 1965. Initial quantities of the windows for the Apollo space vehicle were produced this year, and production of Apollo windows is continuing.

Our phasolver discs, utilizing a complex evaporated metal pattern on a close tolerance glass disc to form a high resolution angular transducer, are in production at Teledyne Optics. Telescopes for NASA’s Orbiting Astronomical Observatory will be pointed and programmed in angle by the phasolvers.

Fluid systems components

The Linair Engineering division of Teledyne, one of the nation’s leading suppliers of hydraulic and pneumatic fittings for aircraft applications, expanded into the industrial fluid fittings market this year.

In addition to strengthening our position in the military and commercial aircraft fitting market, during the year nearly ten per cent of the fittings shipped were for industrial application, a new product area for Teledyne. A substantially increased market penetration for our industrial product line is anticipated for 1965. We intend to introduce a new and fully patented industrial-type fitting, in which significant improvements have been made over competing products. The fitting is expected to have eventual use in aircraft as well as industrial applications.

An important advance was also made in the development of fittings for space applications. We were recently awarded a large contract for a new type fitting designed for use in ground support equipment on the Saturn space vehicle. Selection of Teledyne for this program was significant, since it may well become the only fitting to be used in this application.

An agreement has been made with Lakeland Manufacturing company of Cleveland, Ohio, whereby Lakeland will manufacture our newly developed and patented precision flaring machine for space-type fittings. Sales will be made by both Lakeland Manufacturing and Teledyne to those companies requiring a precision tube flare. To the best of our knowledge, this equipment is the only unit that will meet NASA requirements for tube flares used in space vehicles.

Information display equipment

During 1964 Teledyne entered the field of visual information display equipment, through the acquisition of Radar Relay, Inc. Encouraging progress is being made at Radar Relay in working toward commercial application of its products. As an example, the division recently contracted to provide the complete warning and advisory system for the Douglas DC-9 short-range jet transport. Programs of this type are expected to produce significant increases in our commercial sales over the period of the next few years.

Among the technical developments which took place in this division during 9164 was the development of a new type of four-color miniature switch-indicator. The new switch is the smallest of its kind on the market. It has captured the interest of manufacturers of such equipment as computers, ground control equipment, and aircraft, and is beginning to produce quantity orders.

Under license from the Douglas Aircraft Company, our Radar Relay division has continued the development of a new method of providing advisory or warning information. Known as Auditory Information Display (AID), the system selects the appropriate prerecorded warning message and plays it to the operator of an aircraft or control station to alert him in the event of a malfunction. Tests have shown that human response to an audible warning is as much as six times faster than the response to a lighted indicator.

Working with the Amelco Semiconductor division of Teledyne, Radar Relay has now improved the AID design to a point which should place us in an excellent competitive position. Our in-house capability in microcircuits and integrated circuitry has helped bring about improved performance characteristics with less size and weight at lower cost. The AID development is now under consideration by the Navy for use as a retrofit on its fleet aircraft. It is also being considered for the TFX aircraft, and for use on commercial jet transports.

Explosive ordnance