The Algorithm and Other Musk Musings

The algorithm is the five part process Elon Musk recurses through when running his companies.

“I became a broken record on the algorithm, but I think it’s helpful to say it to an annoying degree.” — Elon Musk

From Zip2, PayPal and X.com to Tesla, SpaceX, and Twitter, few have had as much success at creating new technology companies as Elon Musk. And as it turns out, there is a method, or more aptly, an algorithm behind how Musk makes decisions.

The algorithm consists of five steps, quoted in full from Elon Musk by Walter Isaacson:

Question every requirement. Each should come with the name of the person who made it. You should never accept that a requirement came from a department, such as from “the legal department” or “the safety department.” You need to know the name of the real person who made that requirement. Then you should question it, no matter how smart that person is. Requirements from smart people are the most dangerous, because people are less likely to question them. Always do so, even if the requirement came from me. Then make the requirements less dumb.

Delete any part or process you can. You may have to add them back later. In fact, if you do not end up adding back at least 10% of them, then you didn't delete enough.

Simplify and optimize. This should come after step two. A common mistake is to simplify and optimize a part or a process that should not exist.

Accelerate cycle time. Every process can be speeded up. But only do this after you have followed the first three steps. In the Tesla factory, I mistakenly spent a lot of time accelerating processes that I later realized should have been deleted

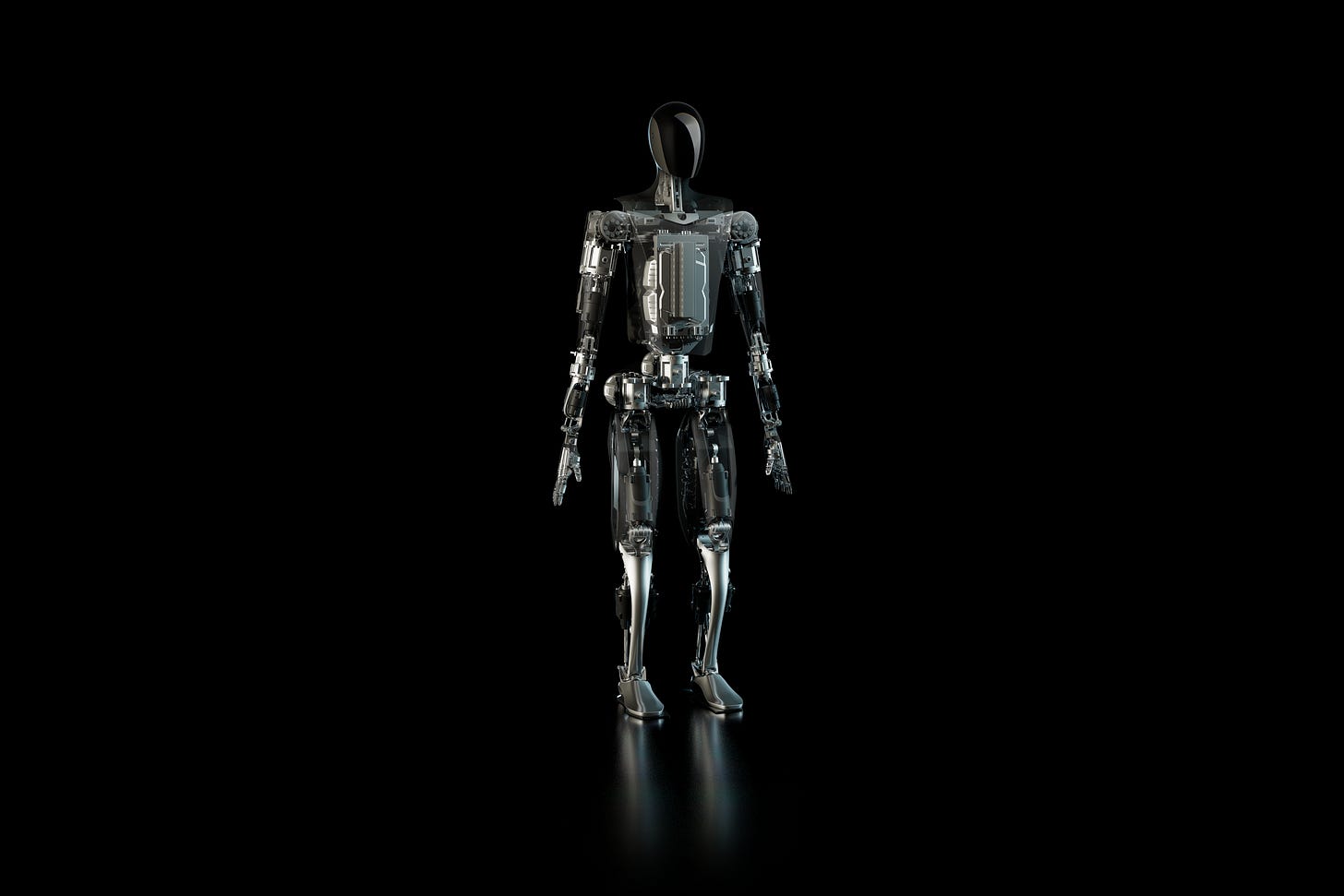

Automate. That comes last. The big mistake in Nevada and at Fremont was that I began by trying to automate every step. We should have waited until all the requirements had been questioned, parts and processes deleted, and the bugs were shaken out.

There are a few other corollaries, a lot of which remind me of parts of Andy Grove’s High Output Management, that Musk favors:

All technical managers must have hands-on experience. For example, managers of software teams must spend at least 20% of their time coding. Solar roof managers must spend time on the roofs doing installations. Otherwise, they are like a cavalry leader who can’t ride a horse or a general who can’t use a sword.

Never ask your troops to do something you’re not willing to do.

Whenever there are problems to solve, don’t just meet with your managers. Do a skip level, where you meet with the level right below your managers.

Comradery can be dangerous. It makes it hard for people to challenge each other’s work and there is a tendency to not want to throw a colleague under the bus.

When hiring, look for people with the right attitude. Skills can be taught. Attitude changes require a brain transplant.

It’s OK to be wrong. Just don’t be confident and wrong.

A maniacal sense of urgency is an operating principle. It’s better to try and fail rather than analyze issues for months. If you make make things fast, you find out fast. And then you can fix it fast.

The only rules are the ones dictated by the laws of physics. Everything else is a recommendation.

Separating the design of a product from its engineering is a recipe for dysfunction. Designers have to feel the immediate pain if something they devised is hard to engineer. When redesigning the factory, Musk put the cubicles for the engineers right on the edge of the assembly lines, so they would see the flashing lights and hear the complaints whenever one of their design elements caused a slowdown.

Design is not just about aesthetics. True industrial design must connect the looks of a product to its engineering. “In most people’s vocabularies, design means veneer,” Steve Jobs once explained. “Nothing could be further from the meaning of design. Design is the fundamental soul of a man-made creation that ends up expressing itself in successive outer layers.”

Think about the cost of things from raw materials, not the market. When a supplier quoted a price of $120,00 for an actuator that would swivel the nozzle of the upper-stage engines, Musk declared it was not more complicated than a garage door opener and told his engineers to make it for $5000. Jeremy Hollman, one of the young engineers working for Mueller, discovered that a valve that was used to mix liquids in a car wash system could be modified to work with rocket fuel.

Turn work into a video game with metrics and high scores. It’s funner that way. You will often lose and it’ll hurt the first fifty times, but when you get used to losing, you will play each game with less emotion.